These applications showcase Long New’s products in tape, medical, electronics, construction, automotive, textiles, and packaging, providing professional materials and solutions based on industry needs.

Tape Industry

BOPP packing tape, cloth tape, double-sided tape, label paper, protective tape, adhesive protective film, etc.

Hygiene and Medical

Hygiene materials (non-woven), medical skin products, wound dressing tape, medical tape, waterproof breathable tape.

3C Industry

Optical films, optical protective films, PCB dry films, flexible circuit board substrates, rigid circuit board substrates.

Construction

PVC embossed wallpaper, PVC mesh, gravure wallpaper, PVC electrical tape, masking tape, fiberglass reinforced tape.

Automotive

Car airbags, seatbelts, flooring, ceilings (non-woven), battery separator film, PVC electrical tape.

Textile & Garment

Waterproof breathable clothing, high-function fabrics, casual fiber products, carbon fiber military materials, tents, raincoats, high-end clothing, casual jackets, sneakers, men’s leather shoes, golf gloves, eco-friendly sofas.

Packaging

Glossy paper, inkjet photo paper, hot stamping film, wine labels, food and product labels.

Food Industry

Food packaging film, food labels, baking paper, lunch box lining.

Long New offers precision coating technologies, customizing solutions based on client needs. Main types, features, and applications:

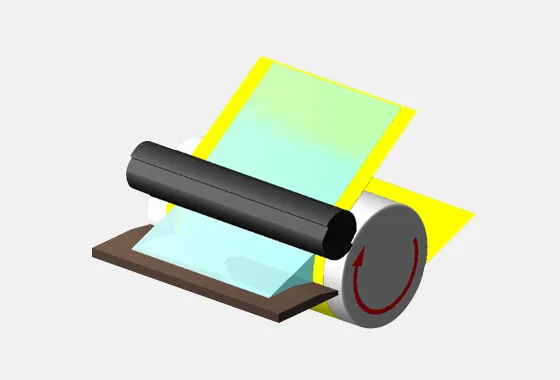

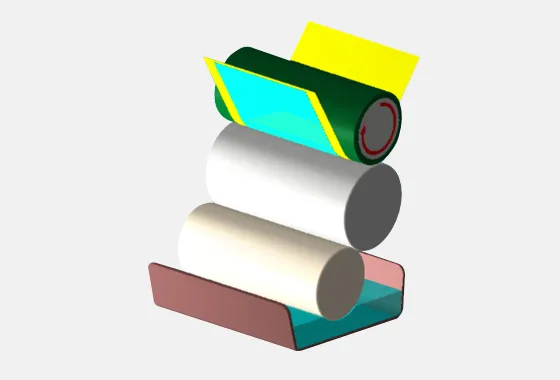

Comma Direct Coating

- Features: Precision, easy to clean, simple operation.

- Applications: 0.1-200m/min, 100-100,000 mPa·s viscosity, 30-2000μm (wet), tape, electronics, medical.

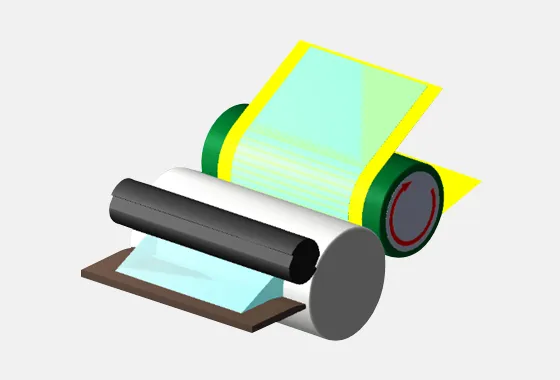

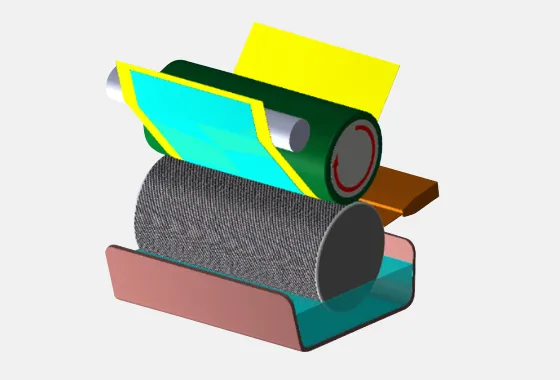

Comma Reverse Coating

- Features: Precision, intermittent coating, easy to clean, simple operation.

- Applications: 0.1-200m/min, 100-50,000 mPa·s viscosity, 20-500μm (wet), tape, battery electrodes.

- Features: High precision, intermittent coating, high volume, high stability.

- Applications: 1-200m/min, 100-50,000 mPa·s viscosity, 10-1000μm (wet), battery electrodes, tape, electronics.

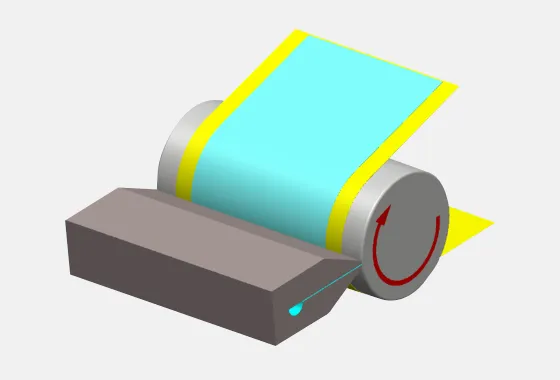

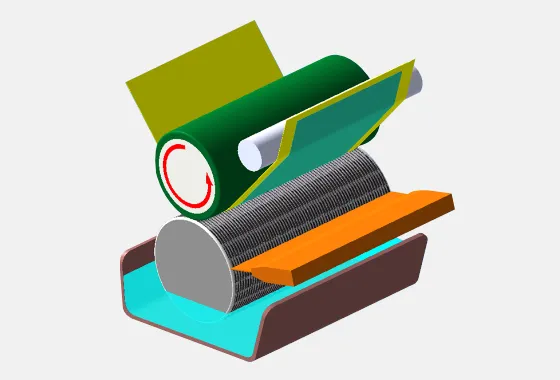

Five-Roll Coating

- Features: Low viscosity, low volume, high speed.

- Applications: 5-500m/min, 10-1000 mPa·s viscosity, 0.5-5μm (wet), release agent coating.

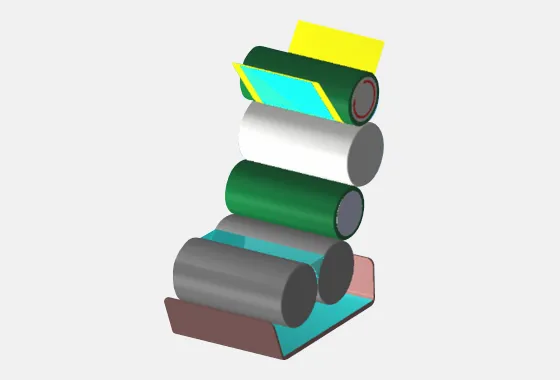

Three-Roll Coating

- Features: High precision, low viscosity.

- Applications: 1-200m/min, 1-1000 mPa·s viscosity, 3-100μm (wet), tape, functional materials.

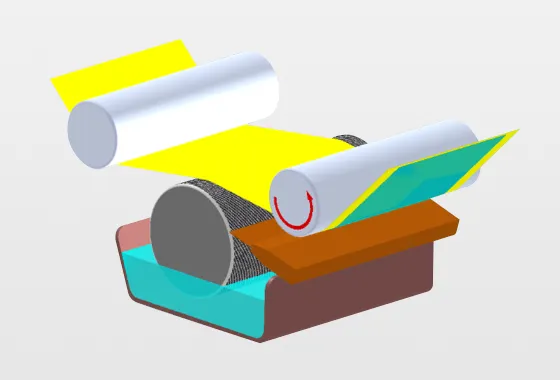

Direct Gravure Coating

- Features: Low volume, low viscosity.

- Applications: 1-300m/min, 1-500 mPa·s viscosity, 1-100μm (wet), release agents, pretreatments, adhesives, functional materials.

Reverse Gravure Coating

- Features: Low volume, low viscosity.

- Applications: 0.1-200m/min, 100-50,000 mPa·s viscosity, 20-500μm (wet), release agents, pretreatments, adhesives, functional materials.

Micro Gravure Coating

- Features: Low volume, low viscosity.

- Applications: 1-300m/min, 1-500 mPa·s viscosity, 1-100μm (wet), release agents, pretreatments, adhesives, functional materials.

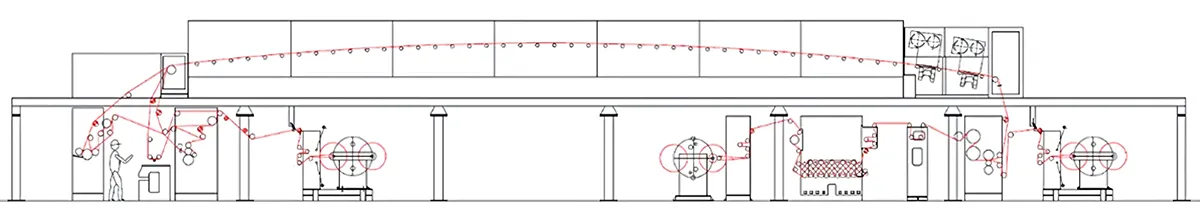

Machine Configuration

| Main Unit | Configuration |

|---|---|

| Unwind/Rewind | Shafted or Shaftless Auto or Manual Splicing |

| Oven | Traditional: Roller or Floating Radiation: IR or UV ※ Note: Based on project, ovens can be used alone or integrated. |

| Coating head | Comma Direct/Reverse, Slot Die, 5-Roll, 3-Roll, Gravure, Reverse Gravure, Micro Gravure, etc. ※ Note: Different methods can coexist on one machine, fixed or convertible trolley. |

| Auxiliary Equipment | Surface Treatment, Static Eliminator, Dust Removal, Gas Detection, etc. |