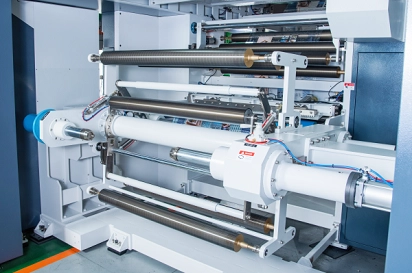

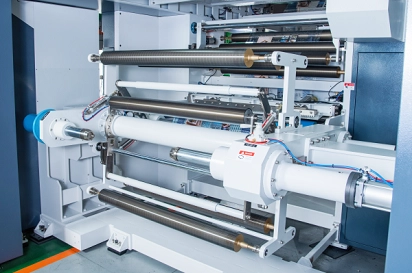

High Speed ELS Rotogravure Printing Machine (Alpha)

Alpha

-

- Running up to 350m/min

- Direct drive ELS system

- Shaftless unwind unit and rewind unit

- New generation color registration system, wastage significantly reduced

- Fully automatic splicing system without human intervention

- Driven inking roller device minimizes ink splash and enhances half tone printing effect

- Highly efficient double-side drying

- Sleeve type impression roller (optional)

- Multi-functional trolley for cylinder and ink tray, productivity largely increased (optional)

- Compatible with water based ink printing

Video Introduction -

Model Alpha Max. web width 1000 mm / 1300 mm Max. machine speed 350 m / min Max. cylinder width 1050 mm / 1350 mm Cylinder repeat 400 - 900 mm Max. unwind dia. 800 mm / 1000 mm (option) Max. rewind dia. 800 mm / 1000 mm (option) Applicable web type All general plastic films, thin paper -

01 Unwinder section

- Shaftless winder, no need for air shafts

- Splicing tail length control

- Inverter control arm rotating

- HMI touch panel

02 Infeed section

02 Infeed section- Web guiding device

- Automatic tension control

- Pre-heat system (option)

03 Printing unit

03 Printing unit- Highly efficient double-side drying performance with energy saving

- Cylinder loading shaftless air chuck system

- Newly designed quick change doctor blade assembly

- Cylinder individually driven

- Cylinder blowing system

- Driven inking roller device minimizes ink splash and enhances half tone printing effect

- Remote color registration touch screen

- Cooling roller driven by servo motor (option)

04 Outfeed

04 Outfeed- Video scanning system

- Automatic color registration interface

- Inspection boards for surface and reverse printing

- Automatic tension control

- H.M.I for easy operation

05 Rewinder

05 Rewinder- Lay-on Roller

- Shaftless winder, no need for air shafts

- Taper tension control (Customized Curves)

- Inverter controlled turret arm rotation

- Fully automatic web splicing

-

Features

- Running up to 350m/min

- Direct drive ELS system

- Shaftless unwind unit and rewind unit

- New generation color registration system, wastage significantly reduced

- Fully automatic splicing system without human intervention

- Driven inking roller device minimizes ink splash and enhances half tone printing effect

- Highly efficient double-side drying

- Sleeve type impression roller (optional)

- Multi-functional trolley for cylinder and ink tray, productivity largely increased (optional)

- Compatible with water based ink printing

Video Introduction -

Specifications

Model Alpha Max. web width 1000 mm / 1300 mm Max. machine speed 350 m / min Max. cylinder width 1050 mm / 1350 mm Cylinder repeat 400 - 900 mm Max. unwind dia. 800 mm / 1000 mm (option) Max. rewind dia. 800 mm / 1000 mm (option) Applicable web type All general plastic films, thin paper -

Detailed Description01 Unwinder section

- Shaftless winder, no need for air shafts

- Splicing tail length control

- Inverter control arm rotating

- HMI touch panel

02 Infeed section

02 Infeed section- Web guiding device

- Automatic tension control

- Pre-heat system (option)

03 Printing unit

03 Printing unit- Highly efficient double-side drying performance with energy saving

- Cylinder loading shaftless air chuck system

- Newly designed quick change doctor blade assembly

- Cylinder individually driven

- Cylinder blowing system

- Driven inking roller device minimizes ink splash and enhances half tone printing effect

- Remote color registration touch screen

- Cooling roller driven by servo motor (option)

04 Outfeed

04 Outfeed- Video scanning system

- Automatic color registration interface

- Inspection boards for surface and reverse printing

- Automatic tension control

- H.M.I for easy operation

05 Rewinder

05 Rewinder- Lay-on Roller

- Shaftless winder, no need for air shafts

- Taper tension control (Customized Curves)

- Inverter controlled turret arm rotation

- Fully automatic web splicing